-40%

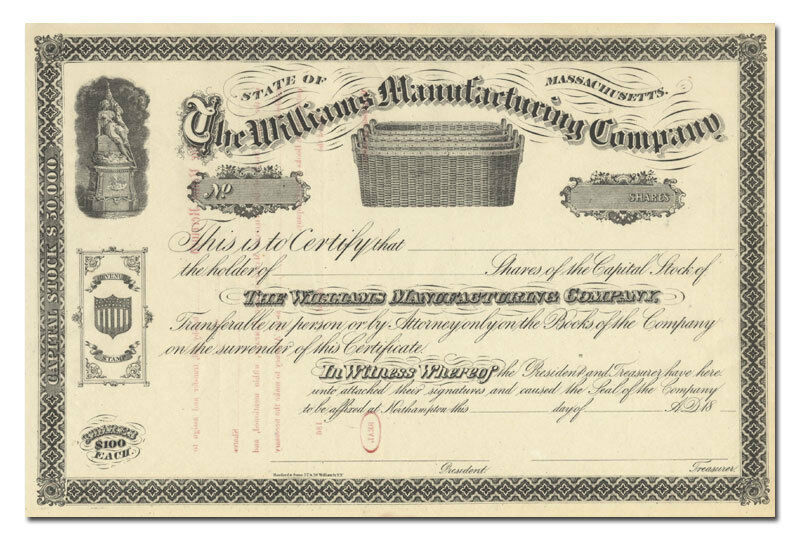

Williams Manufacturing Company Stock Certificate (Massachusetts Basket Maker)

$ 6.32

- Description

- Size Guide

Description

Product DetailsBeautifully engraved antique stock certificate from the Williams Manufacturing Company dating back to the 1800's. This document was printed by Hosford & Sons and measures approximately 11 1/8" (w) by 7 1/4" (h).

This certificate features a pair of great vignettes - a nested group of baskets at the center and an allegorical female figure (Liberty) on a pedestal at the left.

Images

The images presented are representative of the piece(s) you will receive. When representative images are presented for one of our offerings, you will receive a certificate in similar condition as the one pictured; however dating, denomination, certificate number and issuance details may vary.

Historical Context

The Williams Manufacturing Company was incorporated in Massachusetts and based in Northampton. The company manufactured splint and rattan baskets.

L. B. Williams began the business in Huntington, Massachusetts in the mid 19th century with Roland S. Bartlett. The business moved to Northampton in 1862 and the name of the firm was changed to L. B. Williams & Co. In 1867 the concern was incorporated under the name of the William Manufacturing Company, with a capital of 0,000. At the time, the company had the largest basket factory in the world - operated by a seventy-five horse power steam engine, and with the capacity to produce ten thousands baskets per day.

The company used lumber from its own property behind the plant and purchased additional inventory locally, using oak, birch, beech, ash, maple, hickory and elm.

The wood was cut into pieces and soaked a few hours in a steam vat, to make it pliable, after which it was split into pieces of varying thickness, as desired, by machinery. It was then woven in a flat state, like a mat, and was delivered to the finisher. The finisher then bent it over the wooden mould or pattern, forcing it into the required shape. The edges were trimmed off evenly and the rims nailed on quickly.

The company produced verbena and grape baskets; fruit baskets; peach, picking and feed baskets; corn and grain and oyster and clam baskets; covered satchel and market baskets; factory, butchers' and grocers' baskets; office and counter baskets; laundry, clothes, cotton and coal baskets; and hampers of all styles and sizes.